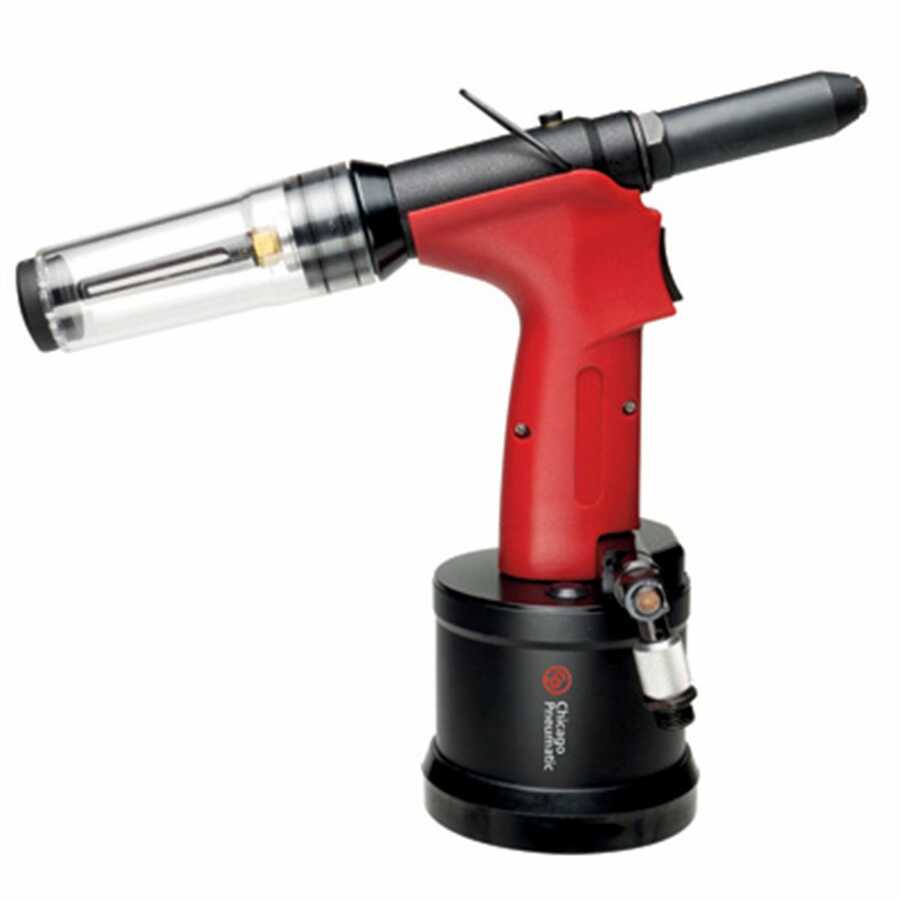

Air Riveters: Essential Tools for Automotive Mechanics

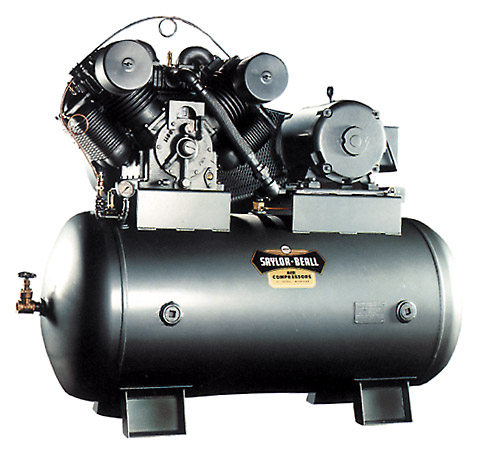

Air riveters are pneumatic tools designed for efficient and precise installation of rivets, particularly useful in automotive repair and maintenance. These tools significantly speed up the process compared to manual methods, offering a crucial advantage in busy repair shops. Mechanics rely on the power and control provided by air riveters to securely fasten various components, from body panels and trim pieces to undercarriage parts and internal mechanisms. The consistent force and speed reduce fatigue, leading to improved accuracy and faster turnaround times on repairs. Selecting the right air riveter depends on the type and size of rivets being used, as well as the specific application. Proper usage involves matching the rivet to the application, choosing the appropriate nose piece, and maintaining the tool's air pressure for optimal performance. Regular maintenance, including lubrication and cleaning, ensures longevity and prevents damage to the tool or the workpiece. Air riveters are an indispensable tool in any professional mechanic's arsenal.

The versatility of air riveters extends to a wide array of automotive applications. From collision repair and bodywork to custom fabrication and modifications, these tools provide a reliable solution for joining materials. Proper training and understanding of different rivet types and their applications are essential for achieving strong, consistent results. This reduces the risk of damage to surrounding materials and ensures lasting repairs. Investing in quality air riveters contributes to increased efficiency, improved repair quality, and ultimately, higher customer satisfaction.

Types of Air Riveters

- Blind riveters

- Pull-type riveters

- Bucking riveters

- Structural riveters

- Heavy-duty riveters

- Micro riveters

- Multi-tool riveters

- Standard riveters

- Specialty riveters

- Electric riveters

Follow us on social media