Belt Tensioning Tools: Essential for Automotive Repair

Maintaining proper belt tension is critical for optimal engine performance and longevity. Improper tension can lead to premature wear, slippage, and even catastrophic engine failure. For automotive mechanics, a reliable set of belt tensioning tools is therefore indispensable, saving valuable time and preventing costly repairs. These specialized tools are designed to safely and efficiently manage the installation and adjustment of serpentine belts, V-belts, and other drive belts found in modern vehicles. Choosing the right tool, whether it's a specific pulley wrench or a more versatile tensioner tool, depends on the make and model of the vehicle. Proper training and familiarity with the vehicle’s system is paramount for safe and effective use.

Key Features and Applications

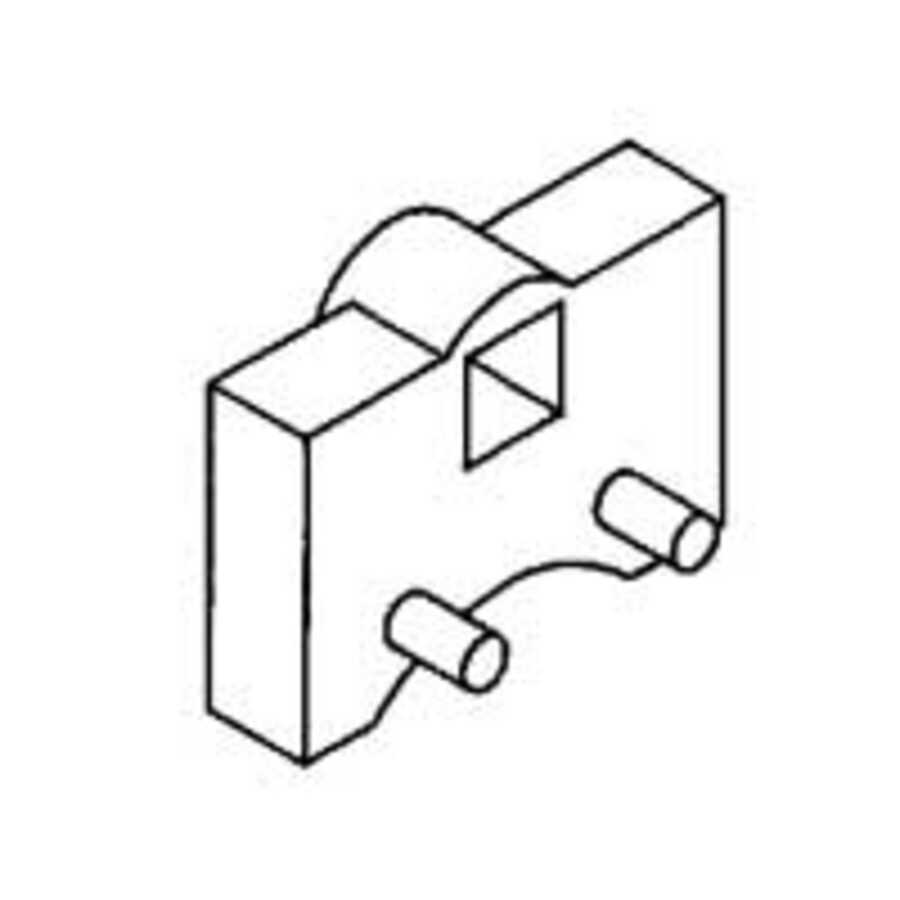

High-quality belt tensioning tools typically feature durable construction, often from hardened steel or chrome vanadium, to withstand the stresses involved in tightening belts. Many incorporate ergonomic designs for comfortable and secure handling, minimizing the risk of injury. Specific features vary depending on the tool; some may include adjustable heads for compatibility with different belt sizes and pulley designs. These tools can be utilized across a broad range of vehicles and engine types, making them a vital component in any professional mechanic's tool kit. Using these precision instruments ensures consistent belt tension, leading to better engine performance and reliability, ultimately benefiting both the mechanic and their clients. The correct application of appropriate torque using a calibrated tensioner prevents premature wear and promotes longevity.

Follow us on social media