Working on a vehicle’s transmission can be a daunting task without the right equipment. This is where a transmission jack comes in. A transmission jack is a specialized tool designed to help mechanics lift and lower transmissions safely and efficiently. In this article, we will delve into the various aspects of using a transmission jack, ensuring you have a comprehensive understanding of its importance, types, usage, and safety measures.

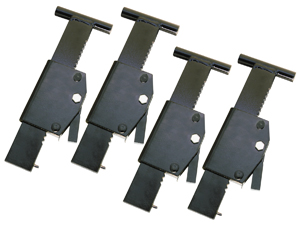

107463 1522A OTC OTC1522A OT1522A OTC-1522A OT1522A 2,000 Lb Capacity Low-Lift Transmission

Types and Categories of Transmission Jacks

Transmission jacks come in various types, each suited for specific applications and preferences. Understanding the different categories can help you choose the right one for your needs.

Hydraulic Transmission Jacks

Hydraulic transmission jacks are widely used due to their ease of operation and robust lifting capacity. They operate using hydraulic fluid to generate the necessary force to lift heavy transmissions with minimal effort. These jacks are ideal for professional settings where frequent use and reliability are paramount.

Pneumatic Transmission Jacks

Pneumatic transmission jacks use compressed air to lift and lower transmissions. These jacks are known for their quick and smooth operation, making them a favorite in high-volume automotive repair shops. They require an air compressor to function, which can be an added expense but is often worth the efficiency gain.

Manual Transmission Jacks

Manual transmission jacks rely on physical effort to operate. They are typically more affordable and are suitable for small garages or DIY enthusiasts who don’t need the speed of hydraulic or pneumatic jacks. While they require more effort, they are reliable and effective for occasional use.

High-Lift Transmission Jacks

High-lift transmission jacks are designed for vehicles that are elevated on a lift. They have a greater height range, allowing them to reach transmissions in vehicles that are significantly raised. These jacks are essential for working on trucks, SUVs, and other high-clearance vehicles.

Low-Lift Transmission Jacks

Low-lift transmission jacks are used for vehicles that are closer to the ground. They provide the necessary lift without the extensive height range of high-lift jacks. These are suitable for standard cars and are easier to maneuver in low-clearance situations.

Diagnosis and Tests

Before using a transmission jack, it’s crucial to diagnose the problem and ensure the jack is in good working condition.

Checking Transmission Issues

Identifying transmission issues is the first step in any repair process. Common signs of transmission problems include unusual noises, difficulty in shifting gears, and transmission fluid leaks. Diagnosing these issues accurately will determine if the transmission needs to be removed and serviced.

Safety Inspections

Before using a transmission jack, conduct a thorough safety inspection. Check the jack for any signs of wear, such as cracks or leaks. Ensure that all moving parts are well-lubricated and that the hydraulic fluid level is adequate. Confirm that the jack’s weight capacity is suitable for the transmission you are working on.

Reasons for Using a Transmission Jack

Using a transmission jack offers several benefits that enhance safety, precision, and efficiency.

Precision and Control

Transmission jacks provide detailed maneuverability, allowing you to position the transmission accurately. This precision is essential for aligning the transmission with the engine and other components during installation or removal.

Safety Enhancements

Working with heavy transmissions poses significant safety risks. A transmission jack minimizes these risks by securely holding the transmission in place, reducing the likelihood of accidents and injuries.

Efficiency in Repair Work

A transmission jack saves time by streamlining the process of lifting and lowering transmissions. This efficiency is particularly beneficial in professional settings where time is a critical factor.

Handling Heavy Loads

Transmissions are heavy and cumbersome. Using a transmission jack makes it easier to handle these loads, ensuring that the transmission is supported throughout the repair process.

Preventive Measures

Maintaining your transmission jack and practicing safe handling are crucial for its longevity and your safety.

Regular Maintenance of the Transmission Jack

Regular maintenance is essential for keeping your transmission jack in optimal condition. Clean the jack after each use to remove dirt and debris. Lubricate moving parts regularly and check for any signs of wear and tear. Replace any damaged components promptly.

Safe Handling Practices

When using a transmission jack, always follow safe handling practices. Ensure the jack is positioned on a flat, stable surface. Use proper lifting techniques to avoid strain. When storing the jack, keep it in a clean, dry place to prevent corrosion and damage.

Personal Stories or Case Studies

Real-life stories and case studies provide valuable insights into the practical use of transmission jacks.

Case Study: Successful Transmission Replacement

Consider a case where a mechanic successfully replaced a transmission using a hydraulic transmission jack. The step-by-step process included safely lifting the vehicle, removing the old transmission, and carefully aligning and installing the new one. The jack’s precision and stability were crucial in completing the job efficiently and safely.

User Experiences

Many automotive professionals share positive experiences with transmission jacks. Testimonials often highlight the ease of use, safety, and efficiency these tools provide. For instance, a technician might recount how a pneumatic transmission jack saved hours of labor and prevented potential injuries.

Expert Insights

Professional advice can help you make the most of your transmission jack.

Professional Tips for Using Transmission Jacks

Experts recommend always checking the jack’s weight capacity before use and ensuring it is suitable for the specific transmission. They also advise positioning the jack correctly to maintain balance and stability.

Common Mistakes to Avoid

Common mistakes include overloading the jack, using it on an uneven surface, and neglecting regular maintenance. Avoiding these pitfalls can prolong the life of your jack and ensure safe operation.

Conclusion

In conclusion, using a transmission jack is essential for safely and efficiently handling transmission repairs. By understanding the types of jacks available, conducting proper diagnosis and safety checks, and following preventive measures, you can make the most of this valuable tool. Always prioritize safety and maintenance to ensure your transmission jack serves you well for years to come.

Follow us on social media