Introduction

Let me paint you a picture: you’re working on your car, knuckles scraped, frustration mounting, and that stubborn wheel just won’t budge. This is where a wheel puller steps in, turning a potential nightmare into a straightforward task. Wheel pullers are indispensable tools in automotive and machinery maintenance, designed to remove wheels, gears, and pulleys that refuse to come off on their own. This article will delve into the world of wheel pullers, highlighting their importance, types, usage, and more.

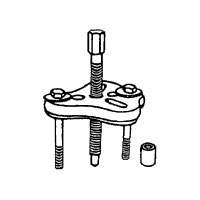

Universal puller for steering wheels with large pull slots, up to 90 mm spread

Mfg: Kukko Quality Tools Inc

Part #: 34-1

Steering wheel puller for steering wheel with spok

Mfg: Kukko Quality Tools Inc

Part #: 32-1

170105 3056 ATD Tools ATD-3056 5T BAR TYPE PULLER/BEARING SET

Mfg: ATD Tools

Part #: 3056

107917 4232SJ Stanley Proto Industrial Tools PO4232SJ 10 Ton PROTO-EASE 2-Way Straight Jaw Puller Set

Mfg: Stanley Proto Industrial Tools

Part #: 4232SJ

Define the Purpose of Wheel Pullers

A wheel puller is a specialized tool used to detach wheels and other components that are press-fitted onto a shaft. They work by applying even force to the component, ensuring it comes off without causing damage. Commonly used in automotive and machinery repairs, wheel pullers are crucial for tasks like removing a wheel hub, pulling off gears, or detaching a steering wheel. Without them, these tasks could lead to damage or require excessive force, potentially ruining the components or, worse, causing injury.

Explain Its Relevance and Importance

Why should you care about wheel pullers? Well, these tools make maintenance more efficient and safe. They prevent damage to vehicle or machine parts by ensuring the force applied is even and controlled. Imagine trying to yank off a wheel with a crowbar; not only is it inefficient, but you risk damaging the wheel and axle. A wheel puller, on the other hand, does the job neatly, maintaining the integrity of your components. Moreover, in professional settings, they enhance productivity by speeding up the repair process.

Types and Categories of Wheel Pullers

Manual Wheel Pullers

Manual wheel pullers are the simplest form. You place the puller onto the wheel, attach the legs to the component, and turn the central screw to apply pressure. They are cost-effective and suitable for smaller tasks, but they require physical effort and are limited by the force you can manually apply.

Hydraulic Wheel Pullers

These are the heavyweights of the wheel puller world. Hydraulic pullers use hydraulic pressure to exert greater force with minimal physical effort. They are ideal for heavy-duty tasks, such as removing large gears or stubborn wheel hubs. However, they are more expensive and require maintenance of the hydraulic system.

Slide Hammer Pullers

Slide hammer pullers use a different approach. Instead of a screw or hydraulic system, a slide hammer is attached to the puller. By sliding the hammer back and forth, you generate force to pull off the component. They are particularly useful for components that are very tightly fitted or in awkward positions.

Specialty Wheel Pullers

There are also specialty pullers designed for specific tasks, such as steering wheel pullers and gear pullers. These are tailored to particular applications, ensuring the best fit and function for the job.

Different Classifications or Types

Wheel pullers can be classified based on their mechanism (manual or hydraulic), application (automotive or industrial), and design (single jaw, double jaw, three jaw). Manual pullers rely on physical force, while hydraulic pullers use fluid pressure. Automotive pullers are designed for vehicle maintenance, whereas industrial pullers are used in heavy machinery. The design classification indicates how many contact points the puller has, which affects its stability and the evenness of force application.

Diagnosis and Tests

Inspecting for Signs of Wheel and Hub Wear

Before using a wheel puller, inspect the wheel and hub for wear or damage. Look for signs of rust, cracks, or deformation, as these could affect the pulling process and indicate deeper issues.

Diagnosing Issues That Require a Wheel Puller

Not all stuck wheels or gears need a puller. Sometimes, a bit of lubricant or a gentle tap will do the trick. Use a puller when components are clearly stuck due to tight press-fits or corrosion that simple methods can’t overcome.

Testing the Effectiveness of the Wheel Puller

After selecting a puller, test it by ensuring it fits securely onto the component. Apply a small amount of force initially to check if it starts to move. This avoids applying excessive force from the start, which could cause damage.

Common Diagnostic Tools and Tests Used

Visual inspection tools are essential for checking wear and alignment. For more complex systems, diagnostic software can identify issues that may require disassembly. Physical testing involves attaching the puller and applying force to see if the component starts to budge.

Reasons for the Tool and Tests

Using the right diagnostic tools and tests ensures the puller is necessary and appropriate for the task. This helps in avoiding unnecessary strain on the components and ensures the puller is used correctly, preventing damage and ensuring a smooth repair process.

Preventive Measures

Regular Maintenance Schedules

Keep a regular maintenance schedule to avoid components becoming so stuck that they require extreme measures to remove. Regular checks and servicing can prevent corrosion and tight press-fits from becoming problematic.

Proper Storage and Care of Wheel Pullers

Store wheel pullers in a dry, clean environment to prevent rust and degradation. Regularly inspect them for signs of wear and maintain them according to the manufacturer’s instructions.

Training for Correct Usage

Ensure that anyone using wheel pullers is properly trained. Incorrect usage can lead to damaged tools or components and even injuries. Training should cover selecting the right puller, attaching it correctly, and applying force safely.

Tips and Strategies to Prevent the Condition

Routine Checks on Wheels and Hubs

Regularly inspect wheels and hubs for signs of wear or tightness. Addressing issues early can prevent the need for aggressive pulling later on.

Using Wheel Pullers Appropriately

Always use the puller as intended. Match the puller to the task and avoid using excessive force. If a component isn’t budging, reassess the situation rather than forcing it.

Avoiding Excessive Force During Use

Excessive force can damage both the component and the puller. Apply force gradually and evenly. If necessary, use penetrating oil to help loosen the component.

Personal Stories or Case Studies

Real-Life Example of a Successful Repair Using a Wheel Puller

Consider John, an amateur mechanic who spent hours trying to remove a wheel hub with a hammer and crowbar, only to damage the hub. After getting a manual wheel puller, he removed the hub in minutes without further damage, completing his repair efficiently.

A Case Study of Avoiding Damage Through Correct Use

In a professional setting, a mechanic used a hydraulic puller to remove a stubborn gear from an industrial machine. By using the right tool and technique, the gear was removed without any damage, saving the company time and money.

Real-Life Implications Through Individual Stories

Mechanics’ Experiences with Wheel Pullers

Many mechanics swear by their wheel pullers, often sharing stories of how these tools saved them hours of labor and prevented damage to valuable components. From removing rusted gears to stubborn wheel hubs, the right puller can make all the difference.

Testimonials from DIY Enthusiasts

DIY enthusiasts often highlight the satisfaction of successfully completing a repair with the right tools. A well-chosen wheel puller can turn a daunting task into a manageable one, boosting confidence and encouraging further DIY projects.

Expert Insights

Quotes from Automotive Professionals

“Using a wheel puller is not just about making the job easier, it’s about doing it right. The correct tool can prevent unnecessary damage and ensure a smooth, safe removal.” – Mark Thompson, Automotive Engineer.

Advice on Choosing the Right Wheel Puller

Experts advise considering the type of job, the size of the component, and the force required. Hydraulic pullers are recommended for heavy-duty tasks, while manual pullers suffice for smaller, less stubborn components.

Tips on Effective Use from Industry Experts

Industry experts emphasize the importance of securing the puller correctly and applying force gradually. They also recommend using lubricants to ease the removal process and prevent rust buildup.

Conclusion

In summary, wheel pullers are essential tools in both automotive and industrial maintenance. They facilitate the safe and efficient removal of wheels, gears, and other components, preventing damage and saving time. By understanding the different types of wheel pullers and their proper use, you can tackle repairs with confidence and precision. So, next time you face a stubborn wheel, remember: a wheel puller is your best friend.

Follow us on social media