Introduction

When it comes to servicing automotive air conditioning systems, having the right tools is as crucial as having the right skills. I remember a time when I was helping a friend with a seemingly minor AC issue. We struggled with it for hours until we realized we lacked a simple yet essential tool—a manifold gauge set. That experience taught me the value of having a complete and reliable toolkit, especially for AC services. In this listicle, we’ll explore some of the most essential tools every technician needs for efficient AC servicing and how these tools can make or break your repair process.

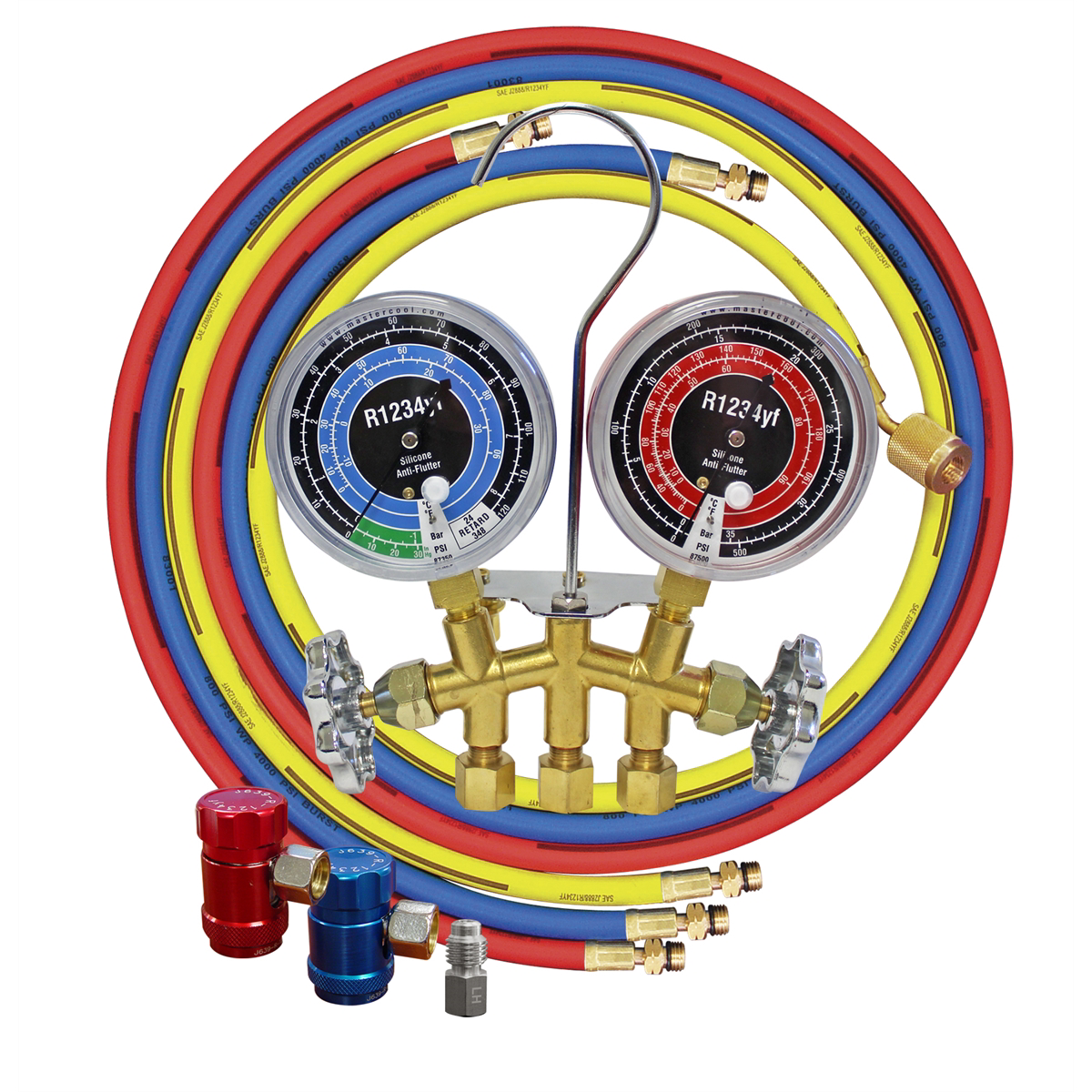

Tool #1: Manifold Gauge Set

A manifold gauge set is indispensable for anyone working on automotive air conditioning systems. It allows technicians to check the pressure in the AC system, which is vital for diagnosing issues and recharging refrigerants. The gauges provide insights into both the high-pressure and low-pressure sides of the system, helping identify leaks and performance issues.

Types of Manifold Gauge Sets

There are different types of manifold gauge sets available, including analog and digital versions. Analog gauges are traditional, easy to use, and often more affordable. They provide reliable readings with a simple needle-and-dial interface. Digital gauges, on the other hand, offer more precision and additional features such as automatic calculations and data storage.

Best Practices

To ensure accurate readings, it’s important to regularly calibrate your manifold gauge set and check for any signs of wear and tear. Proper maintenance extends the lifespan of your tools and ensures reliable performance. Always make sure the valves are tightly closed when not in use to prevent contamination and leaks.

Tool #2: Vacuum Pump

A vacuum pump is essential for removing air and moisture from an AC system before recharging it with refrigerant. This step is crucial because air and moisture can cause corrosion and reduce the efficiency of the system.

Choosing the Right Vacuum Pump

When selecting a vacuum pump, consider factors such as pumping speed (measured in cubic feet per minute, or CFM) and ultimate vacuum level (measured in microns). A higher CFM means faster evacuation, while a lower micron rating indicates a stronger vacuum.

Tips for Effective Use

Before using a vacuum pump, ensure that all connections are secure and there are no leaks in the system. Allow the pump to run long enough to reach the desired vacuum level, typically between 500 and 1000 microns. A longer evacuation time might be necessary for larger systems or those with significant moisture content.

Tool #3: Refrigerant Leak Detector

Refrigerant leaks can be a nightmare to find without the right equipment. A refrigerant leak detector is a critical tool for pinpointing leaks in the AC system. These detectors come in various types, such as electronic and UV dye, each with its advantages.

Types of Leak Detectors

- Electronic Leak Detectors: These use sensors to detect changes in air composition and are sensitive to small leaks.

- UV Dye Leak Detectors: These involve injecting a UV-sensitive dye into the system. A UV light is then used to inspect for leaks, where the dye becomes visible.

Effective Leak Detection

It’s advisable to use both electronic and dye methods for comprehensive leak detection. Always check all potential leak points, including hose connections, fittings, and seals. Regular leak detection can prevent costly repairs and ensure the longevity of the AC system.

Tool #4: Recovery Machine

Using a recovery machine is not only a best practice but also a legal requirement when servicing AC systems. It allows technicians to safely recover and recycle refrigerant, reducing environmental impact and ensuring compliance with regulations.

Features to Look For

Modern recovery machines are designed to be efficient and user-friendly. Look for features such as automatic shut-off when the recovery is complete, oil-less compressors for reduced maintenance, and compatibility with various refrigerants.

Environmental Considerations

Proper refrigerant recovery is crucial for minimizing environmental impact. Always adhere to local regulations regarding refrigerant handling and disposal. Investing in a high-quality recovery machine can improve efficiency and ensure compliance with environmental standards.

Tool #5: Thermometer

Thermometers are essential for assessing the performance of an AC system. They help measure the temperature of the air coming from the vents, allowing technicians to determine if the system is cooling as expected.

Types of Thermometers

- Infrared Thermometers: These provide quick, non-contact temperature readings. They are ideal for measuring surface temperatures and are widely used for their convenience.

- Traditional Thermometers: These require contact with the air or surface being measured. They are often used for verifying the accuracy of infrared readings.

Utilizing Thermometers Effectively

To get accurate temperature readings, ensure the thermometer is properly calibrated and free of obstructions. Compare readings at various points in the system to identify any inconsistencies. Regular monitoring of temperatures can help detect issues before they escalate into major problems.

Tool #6: Flush Kit

A flush kit is vital for cleaning the AC system and removing any contaminants or debris. This process ensures that the new refrigerant circulates properly and the system operates at peak efficiency.

Importance of Flushing

Flushing the AC system is especially important after a component failure, such as a compressor breakdown. It removes metal particles and other debris that can cause damage to new components.

Steps for Effective Flushing

- Disconnect the Compressor: Prevents damage to the new compressor during the flushing process.

- Use the Right Solvent: Select a solvent compatible with the AC system materials.

- Follow Manufacturer Instructions: Adhere to guidelines to ensure thorough cleaning.

- Dry the System Completely: Use compressed air to remove any remaining solvent before reassembly.

Tool #7: AC Line Disconnect Tools

AC line disconnect tools are necessary for separating the AC lines without damaging them. These tools make it easier to access and replace components within the system.

Types and Uses

These tools come in various designs, such as pliers and quick-disconnect sets, each suited for different types of fittings and lines. Using the correct tool for the specific fitting is crucial for avoiding damage.

Advantages of Using Disconnect Tools

Using the right disconnect tool saves time and reduces the risk of damaging components, which can lead to costly repairs. They are particularly useful when dealing with complex systems that require frequent disassembly and reassembly.

Conclusion

Investing in quality tools for AC service is not just about making the job easier; it’s about ensuring the job is done right. Whether you’re a seasoned technician or a DIY enthusiast, having the right tools can make all the difference. Evaluate your current toolset and consider upgrading to enhance your efficiency and effectiveness in servicing automotive AC systems. Each tool mentioned here plays a pivotal role in the maintenance and repair process, ensuring that systems operate efficiently and effectively.

FAQs

What are the benefits of using a manifold gauge set?

A manifold gauge set allows you to measure the pressure within the AC system accurately, helping diagnose issues and recharge refrigerants safely.

How often should I calibrate my tools?

Regular calibration is essential for maintaining accuracy. It’s recommended to calibrate tools at least once a year or whenever you notice inconsistencies.

What safety precautions should I take during AC service?

Always wear safety goggles and gloves, work in a well-ventilated area, and ensure that all equipment is in good working condition to prevent accidents.

Why is refrigerant recovery important?

Refrigerant recovery is essential to prevent environmental harm and comply with legal requirements regarding the handling and disposal of refrigerants.

How can I ensure the longevity of my AC service tools?

Regular maintenance, proper storage, and following the manufacturer’s instructions can significantly extend the life of your tools.

Follow us on social media