Chrysler Specialty Tools: Essential Equipment for Efficient Repairs

Chrysler vehicles, known for their innovative engineering and diverse model range, often require specialized tools for accurate and efficient repairs. These tools, ranging from simple diagnostic equipment to complex engine component removal systems, are indispensable for any professional mechanic working on Chrysler automobiles. Having the correct Chrysler repair tools ensures proper fitment, prevents damage to vehicle components, and ultimately saves time and money by streamlining the repair process. Proper torque wrench usage and specific socket sizes are critical for many Chrysler repairs. Access to the right diagnostic scanners and software is also paramount for identifying and resolving complex electrical and electronic issues.

Key Features and Applications of Chrysler Specialty Tools

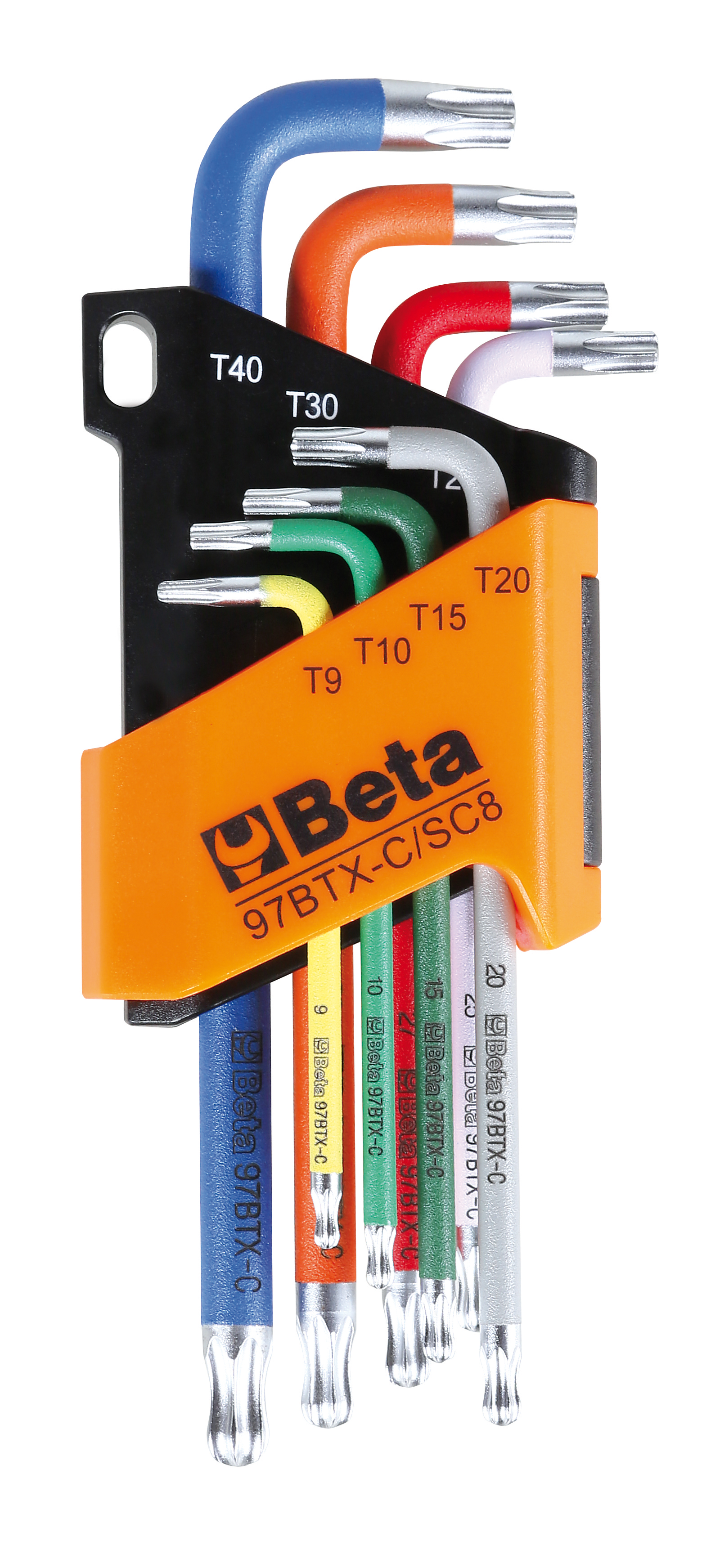

A comprehensive set of Chrysler specialty tools typically includes a variety of components designed to address specific repair challenges. This can range from specialized sockets and wrenches designed for unique fastener geometries found in Chrysler engines and transmissions, to tools that facilitate proper alignment and removal of various engine components. The use of these tools is crucial when dealing with unique engine designs, fuel system components, and security fasteners. Proper use of these tools minimizes the risk of damage to delicate components, improving efficiency and repair quality. Accurate and safe removal and installation of various parts, such as suspension components and body panels, depend heavily on the availability of these specialized tools. Investing in a robust set of these tools is therefore a strategic decision for any professional mechanic who regularly services Chrysler vehicles.

Follow us on social media