Combustion Leak Detectors: Essential Tools for Automotive Mechanics

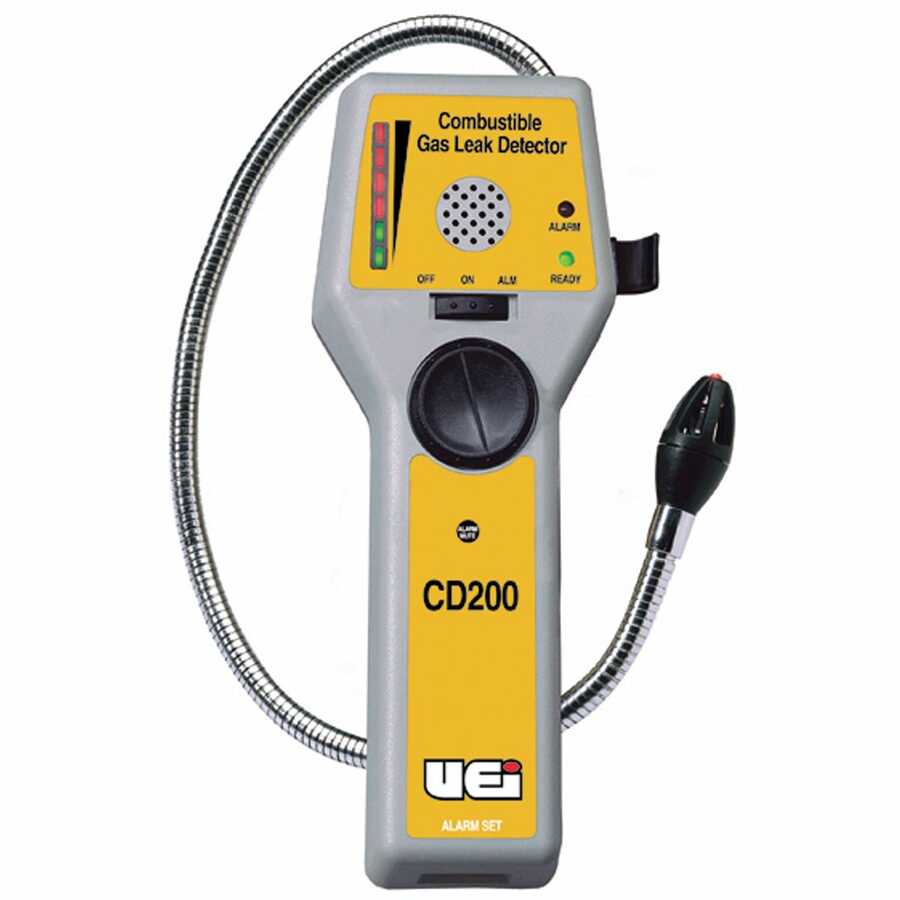

Combustion leak detection is critical for efficient engine repair and emissions compliance. Accurate diagnosis of leaks in exhaust systems, intake manifolds, and even within the combustion chamber itself significantly reduces repair time and ensures the vehicle operates optimally and meets regulatory standards. Modern detectors offer enhanced sensitivity and various detection methods, making them invaluable diagnostic instruments in any professional automotive shop. Using the right equipment to pinpoint the source of a leak is paramount to effective repair, saving both time and potentially expensive trial-and-error troubleshooting. Choosing a detector with durable construction and reliable performance is a smart investment.

Key Features and Applications of Combustion Leak Detectors

Many combustion leak detectors utilize advanced sensor technology for precise leak location. These advanced tools often employ smoke injection techniques, pressure differential measurements, or even specialized gas analyzers to identify even the smallest leaks. This precision allows mechanics to quickly diagnose problems related to vacuum leaks, exhaust leaks, and other combustion-related issues, leading to faster repair times. The choice of detector will depend on the specific application and the type of leaks anticipated, with some models being more suitable for specific tasks like finding extremely small vacuum leaks in fuel injection systems or detecting larger exhaust leaks. Proper use and regular calibration of these tools are essential for accurate readings and reliable diagnostic results, contributing to the overall efficiency and precision of vehicle maintenance and repair. Investing in high-quality equipment ensures precise results and contributes to a professional reputation.

Follow us on social media